Core bits are the critical tool in mineral exploration and construction drilling. The design and manufacturing precision and design are vital, but beyond these, the foundation of any truly good quality core bit lies in its raw material. The indispensable component of a high-performance bit is tungsten carbide powder (WC). Renowned for its exceptional hardness, wear resistance, and ability to withstand immense pressure and heat, tungsten carbide is the key to efficient penetration through the most challenging hard rock, concrete, and abrasive formations.

Global Market Challenges: Rising Price of Tungsten Carbide Powder

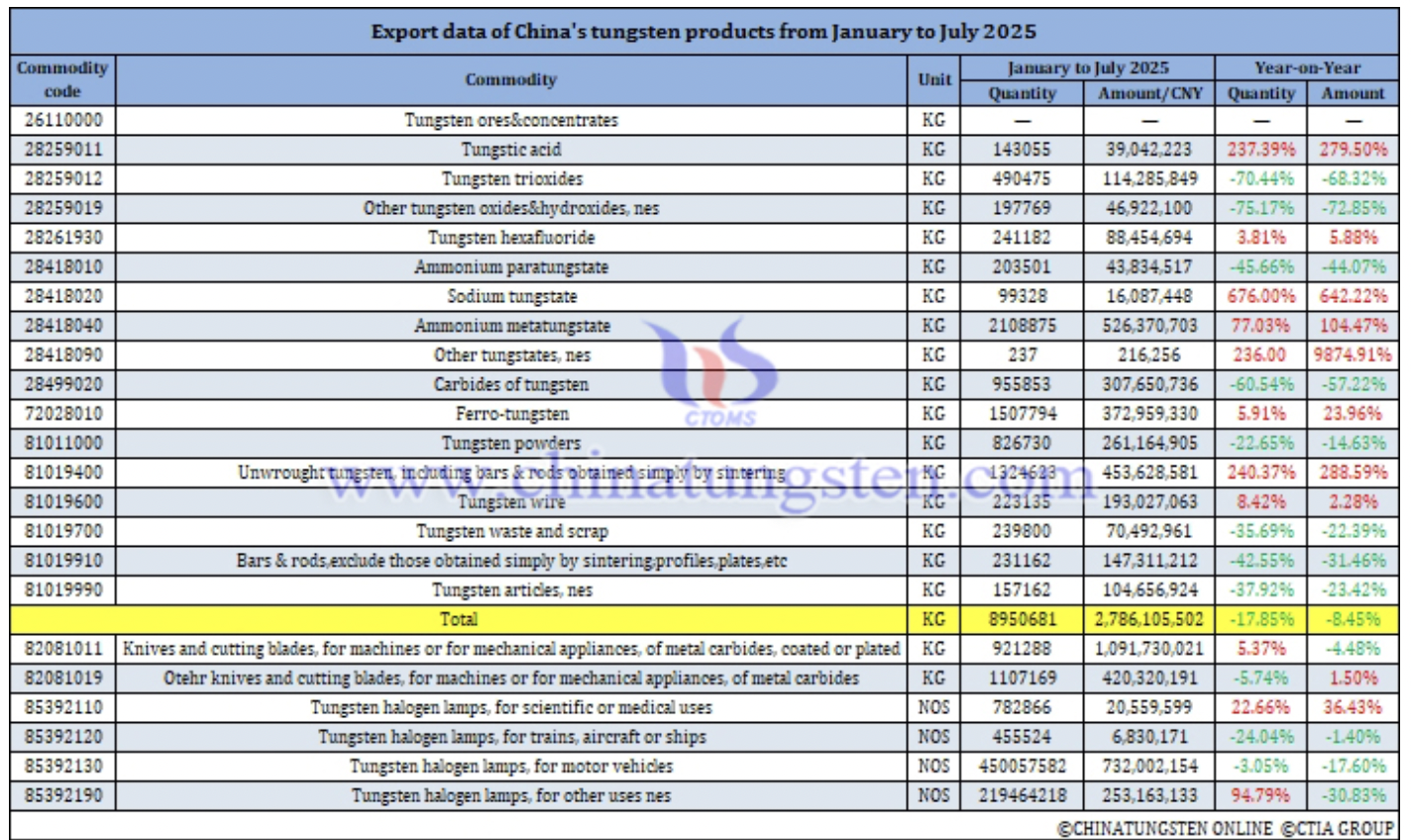

In 2025, the drilling industry have been facing a significant challenge, which is the rising cost and increased volatility of tungsten. As the primary material for carbide inserts, the price of tungsten carbide powder has seen substantial increases globally. According to data compiled by China Tungsten Online from the General Administration of Customs, from January to July 2025, China's exports of tungsten products (excluding cemented carbide tools and tungsten halogen lamps) reached 8,950.68 tons, a year-on-year decrease of 17.85% compared to the same period in 2024. The export value amounted to RMB 2.786 billion, reflecting a year-on-year decrease of 8.45% [1].

Market pressures seems to force manufacturers to cut raw material costs to stay competitive. This leaves users having to choose between budget constraints and the need for premium materials that ensure reliable performance.

ROCKCODE's Answers

ROCKCODE chooses to maintain our material quality standards despite market pressures. We believe true value comes from reliable performance and lower total cost of ownership, when the price becomes truly competitive:

1. Consistent High-quality Material Standards

Despite market pressures, ROCKCODE still keep sourcing high-quality tungsten carbide powder from global leading companies such as Kennametal Inc and Sandvik. Compromising on material quality often greatly impacts bit life and performance consistency, leading to more frequent replacements and downtime. By maintaining our material standards, ROCKCODE bits show dependable performance in the field.

2. Shared Market Risk with Customers

With tungsten carbide powder prices fluctuating significantly, ROCKCODE chooses to share the market pressures rather than pass all cost increases to customers. We are willing to accept tighter margins when needed to maintain both high quality standards and competitive pricing in the premium market segment. This partnership approach helps our customers manage project costs while still accessing the performance benefits of high-quality bits.

3. Comprehensive Quality Control for Consistency

Quality raw materials are just the starting point. ROCKCODE implements quality control throughout production: from incoming material inspection to the process monitoring and to the final product testing. This ensures our bits consistency, which helps reduce rework and operational delays caused by tool failure.

4. Lowering Your Total Operational Cost

A high-quality core bit is a long-term investment. ROCKCODE bits, built with quality materials and precision manufacturing for good wear resistance and services life. This means longer replacement intervals, fewer bit changes, and less equipment downtime. While the initial purchase price is always a consideration, the lower total operating cost, considering meters drilled per bit, reduced inventory needs, and improved site efficiency, makes ROCKCODE a more economical choice. Such idea is well accepted in the drilling industry that evaluating tools by total cost of ownership (TOC) rather than unit price is important practice among successful drilling contractors [2].

5. Personalized Technical Expertise and On-site Support

ROCKCODE’s commitment extends far beyond the product itself. Drawing on over a decade of manufacturing experience and a rich database of practical geological data, we provide practical application support.

- Targeted Design: We offer solutions suited to specific ground conditions, whether hard abrasive rock, soft sticky formations, or complex interbedded geology.

- Parameter Optimization: Our team can help select appropriate drilling parameters (RPM, weight on bit, flushing method) for your ground conditions to improve penetration rates and core recovery.

- Technical Partnership and Field Support: ROCKCODE provides guidance on proper bit use and maintenance to minimize wear from misuse. Believing in field support philosophy, we work directly with customers to address field challenges and optimize performance.

The Buyer's Guide for Core Bits

With challenging tungsten carbide powder prices, smart buyers are adjusting their purchasing approach beyond just comparing unit prices.

-

Calculate total cost per meter drilled, including bit life and downtime. A premium bit that lasts longer often costs less overall than cheaper alternatives.

-

Stick with suppliers maintaining quality standards during market volatility. Those sourcing from established tungsten carbide producers tend to offer more predictable performance than manufacturers switching to cheaper materials.

-

Look for partnership-minded suppliers who share market pressures rather than passing all cost increases to customers. This signals genuine long-term commitment.

-

Demand full-process quality control from material inspection through final testing. Consistency prevents costly field surprises.

-

Use technical support services. Proper bit selection and drilling parameters can extend tool life significantly—your best defense against rising costs.

→ For more information about ROCKCODE’s Good Quality Core Bits, please visit: https://www.rockcodebit.com/product

→ Email us at: info@rockcodebit.com

→ Information in this article is for general reference only. For specific drilling projects and drilling bits, please consult qualified professionals. Thank you.

[1] China’s Tungsten Products Exports from January to July 2025 https://www.ctia.com.cn/en/news/43803.html

[2]https://www.epiroc.com/en-us/products/rock-drilling-tools/tophammer/epiroc-underground-drill-bits?