Grease pumps play a crucial role in the maintenance and longevity of machinery across numerous industries. From automotive workshops to manufacturing plants and heavy construction sites, these devices make sure that equipment remains properly lubricated, reducing friction and preventing premature wear. Without an effective lubrication system, mechanical components can overheat, seize, or fail entirely. Grease pumps provide a steady and controlled way to deliver grease to essential parts, making them an indispensable tool for technicians, mechanics, and engineers. As machinery becomes more advanced, the demand for reliable grease pumping systems continues to grow.

Certainly one of the most important advantages of grease pumps is their ability to supply precise amounts of lubrication wherever it's needed. Over-greasing and under-greasing are both electric grease pump common issues in manual lubrication, often ultimately causing seal damage or insufficient protection. Grease pumps—whether manual, pneumatic, electric, or battery-powered—are designed to solve these problems by offering accurate, efficient, and repeatable grease delivery. For industries that depend on heavy machinery, such precision is important to reducing downtime and increasing equipment lifespan. By ensuring optimal lubrication levels, grease pumps help machinery operate more smoothly and efficiently.

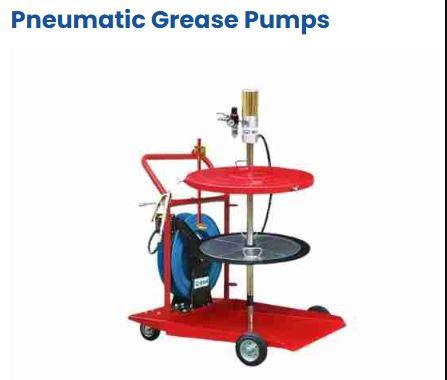

Different types of grease pumps serve different operational needs. Manual pumps are simple, portable, and suited to small workshops or tasks that want occasional lubrication. Pneumatic grease pumps are widely utilized in industrial environments where high volume and rapid delivery are necessary. Electric and battery-powered models bring convenience and good performance without the necessity for air compressors. Each form of grease pump offers unique advantages, and selecting the right choice depends upon the user's workload, environment, and equipment requirements. Businesses often purchase multiple types to cover a wide selection of lubrication tasks.

Maintenance and proper usage will also be key factors in maximizing the potency of grease pumps. Regular cleaning prevents clogs, while routine inspections make certain that seals, hoses, and fittings remain in good working condition. Technicians must also match the pump with the right grease grade and maintain correct pressure levels in order to avoid equipment damage. Training employees to use grease pumps safely and correctly improves operational efficiency and reduces workplace accidents. Well-maintained grease pumps not merely extend machinery life but also save companies time and money by reducing repair costs and labor hours.

In conclusion, grease pumps are essential tools for maintaining the health and performance of machinery in just about any industry. Their ability to deliver precise lubrication, with the availability of varied types tailored for different tasks, makes them incredibly versatile and reliable. An adequately selected and maintained grease pump can greatly improve equipment reliability, enhance safety, and reduce operational costs. As industries continue to cultivate and machinery becomes more sophisticated, grease pumps will remain a vital component of effective maintenance programs. For businesses looking to protect their investment in machinery, grease pumps are a smart, practical, and long-term solution.

Certainly one of the most important advantages of grease pumps is their ability to supply precise amounts of lubrication wherever it's needed. Over-greasing and under-greasing are both electric grease pump common issues in manual lubrication, often ultimately causing seal damage or insufficient protection. Grease pumps—whether manual, pneumatic, electric, or battery-powered—are designed to solve these problems by offering accurate, efficient, and repeatable grease delivery. For industries that depend on heavy machinery, such precision is important to reducing downtime and increasing equipment lifespan. By ensuring optimal lubrication levels, grease pumps help machinery operate more smoothly and efficiently.

Different types of grease pumps serve different operational needs. Manual pumps are simple, portable, and suited to small workshops or tasks that want occasional lubrication. Pneumatic grease pumps are widely utilized in industrial environments where high volume and rapid delivery are necessary. Electric and battery-powered models bring convenience and good performance without the necessity for air compressors. Each form of grease pump offers unique advantages, and selecting the right choice depends upon the user's workload, environment, and equipment requirements. Businesses often purchase multiple types to cover a wide selection of lubrication tasks.

Maintenance and proper usage will also be key factors in maximizing the potency of grease pumps. Regular cleaning prevents clogs, while routine inspections make certain that seals, hoses, and fittings remain in good working condition. Technicians must also match the pump with the right grease grade and maintain correct pressure levels in order to avoid equipment damage. Training employees to use grease pumps safely and correctly improves operational efficiency and reduces workplace accidents. Well-maintained grease pumps not merely extend machinery life but also save companies time and money by reducing repair costs and labor hours.

In conclusion, grease pumps are essential tools for maintaining the health and performance of machinery in just about any industry. Their ability to deliver precise lubrication, with the availability of varied types tailored for different tasks, makes them incredibly versatile and reliable. An adequately selected and maintained grease pump can greatly improve equipment reliability, enhance safety, and reduce operational costs. As industries continue to cultivate and machinery becomes more sophisticated, grease pumps will remain a vital component of effective maintenance programs. For businesses looking to protect their investment in machinery, grease pumps are a smart, practical, and long-term solution.