In the current rapidly developing industrial field, the selection of materials is crucial for the performance and cost control of products. Aerospace Interior Trim Profiles are receiving increasing attention and favor due to their excellent physical properties, lightweight characteristics and multi-functional applications. This article will conduct a detailed analysis of Aerospace Interior Trim Profiles, including its definition, advantages, application fields, processing techniques and future development trends, providing comprehensive references for enterprises when choosing materials.

I. Overview of Aerospace Interior Trim Profiles

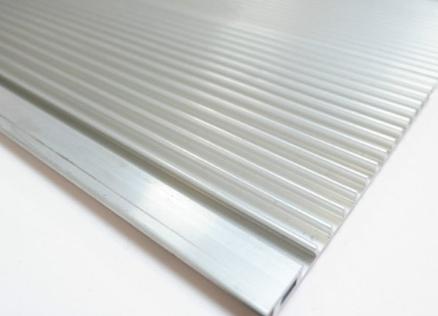

Aerospace Interior Trim Profiles refer to various aluminum profiles made by extrusion forming process based on aluminum and aluminum alloys. These profiles are usually lightweight, high-strength and have good corrosion resistance, and are widely used in many industries such as construction, transportation, electronics and aviation. As one of the important materials in modern industry, aluminium profiles have become the preferred material for many enterprises in product design and manufacturing due to their unique characteristics and advantages.

Ii. Advantages of Aerospace Interior Trim Profiles

1. Lightweighting: The density of aluminium is only one-third that of steel, which enables aluminium profiles to significantly reduce the overall weight during product manufacturing, thereby enhancing the operability and transportation efficiency of the products.

2. High strength: Despite the relatively low density of aluminium, through alloying and appropriate heat treatment processes, the strength of aluminium profiles can rival that of some high-strength steels, effectively meeting the usage requirements under high-load working conditions.

3. Corrosion resistance: The naturally formed oxide film on the surface of aluminum can effectively resist corrosion, especially in damp or chemically corrosive environments, which gives it an advantage over other metal materials. This extends the service life of products using aluminium profiles and reduces maintenance costs.

4. Strong processability: Aluminum and its alloys have excellent processability and can be processed through various techniques such as cutting, welding, and bending to meet the design requirements of different shapes and sizes.

5. Environmental friendliness: Aluminum is a recyclable material, and the energy consumption during the recycling process is relatively low, which helps to reduce the overall environmental impact. With the enhancement of global environmental awareness, the sustainable development advantages of aluminium profiles have become increasingly prominent.

Iii. Application Fields of Aerospace Interior Trim Profiles

1. Construction industry: In the construction industry, aluminum profiles are widely used in structures such as window frames, curtain walls, doors, and elevator shells. Due to its lightweight and corrosion-resistant properties, aluminium profiles can effectively enhance the aesthetic appeal and service life of buildings.

2. Transportation industry: In the manufacturing of automobiles, railways, aviation and other means of transportation, aluminum profiles can not only reduce the overall weight but also improve fuel efficiency, making them a key material for lightweight design at present.

3. Electronics Industry: The high heat dissipation requirements of electronic products have given rise to the wide application of aluminum profiles in the electronics industry, especially in areas such as heat sinks, casings, and brackets. Aluminum profiles, with their excellent thermal conductivity, perfectly meet market demands.

4. Mechanical equipment: Among the components such as frames, brackets, and guide rails of various mechanical equipment, aluminum profiles have become the ideal choice due to their high strength and rigidity, along with excellent processability.

5. Furniture and Decoration: Aluminum profiles are gradually being used in modern furniture design, including tables, chairs, cabinets, etc. Their fashionable and simple appearance and the excellent properties of aluminum itself make the furniture more modern.

Iv. Processing Technology of Aerospace Interior Trim Profiles

The production of Aerospace Interior Trim Profiles involves multiple key steps:

1. Extrusion forming: This process is the core of aluminum profile production. By heating aluminum ingots to a certain temperature and then extruding them through molds, aluminum profiles with different cross-sections are formed.

2. Surface treatment: The surface treatment methods for aluminum profiles typically include anodizing, electrophoretic painting, and spraying, etc. These processes not only enhance the corrosion resistance of aluminum profiles but also offer a variety of color and appearance options.

3. Welding and Assembly: During the final assembly of the product, aluminum profiles usually need to be constructed into specific structural bodies through welding or mechanical connection and other methods.

4. Heat treatment: Through heat treatment processes, the strength and hardness of aluminum profiles can be further enhanced, which is particularly important in high-load applications.

V. Future Development Trends

With the advancement of technology, the application of aluminium profiles will become increasingly widespread, and at the same time, their production techniques and material innovations will also continue to improve. The following are the possible future development trends:

1. Intelligent manufacturing: By introducing advanced technologies such as the Internet of Things and artificial intelligence, the production of aluminum profiles will become more intelligent, achieving more efficient production management and quality control.

2. New alloy materials: Develop new aluminum alloy materials to enhance strength, corrosion resistance and heat resistance, in order to meet more stringent industry standards and special requirements.

3. Environmentally friendly materials: With the advancement of the green economy, the demand for environmentally friendly aluminum profiles is constantly increasing, and the related production processes will also develop in a more environmentally friendly and sustainable direction.

4. Personalized Customization: Future market demands will tend towards personalization and customization. Aluminum profiles will become more flexible to meet the specific needs and design concepts of different customers.

To sum up, Aerospace Interior Trim Profiles, with their excellent performance and broad application prospects, have become indispensable important materials in modern industry. Through continuous technological innovation and process improvement, aluminum profiles will play a greater role in more fields in the future, contributing to the sustainable development of various industries.

Aerospace Interior Trim Profiles https://www.rongxinhao.com/Aerospace-interior-trim-profile.html